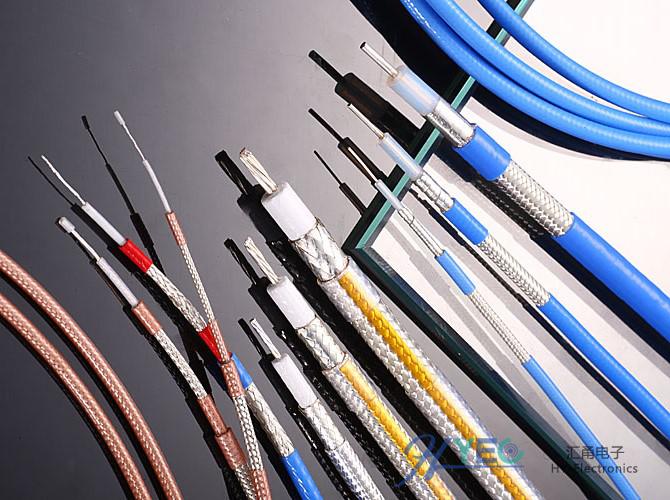

What is a coaxial cable?

Coaxial Cables are sometimes referred to as RF Cables, which are the most common type of construction. Since the inner and outer conductors are in a concentric position, the electromagnetic energy is confined to propagate in the medium between the inner and outer conductors, so that it has the advantages of small attenuation, high shielding performance, use frequency bandwidth and stable performance. Usually used to transmit RF energy from 500 kHz to 18 GHz. A coaxial cable has two concentric conductors, and the conductor and shield share a cable of the same axis. The most common coaxial cable consists of a copper wire conductor isolated by an insulating material. On the outside of the inner insulating material is another layer of ring conductor and its insulator, and then the entire cable is covered by a sheath of polyvinyl chloride or Teflon material. . Coaxial cable can be divided into RF coaxial cable with 50Ω baseband cable and 75Ω wideband cable. The baseband cable is divided into a thin coaxial cable and a thick coaxial cable. The baseband cable is only used for digital transmission and has a data rate of up to 10Mbps. Characteristic impedance 50Ω RF coaxial cable is mainly used for baseband signal transmission, transmission bandwidth is 1~20MHz, characteristic impedance 75Ω RF coaxial cable is often used in CATV network, so it is called CATV cable, transmission bandwidth can reach 1GHz, currently used CATV cable The transmission bandwidth is 750MHz.

Coaxial cable structure and materials

The most important electrical properties of a cable are low attenuation, uniform impedance, and high return loss. The key to leaking cables is their optimum coupling loss. The main function of the cable is to transmit the signal, so it is important that the cable construction and materials ensure good transmission characteristics throughout the life of the cable.

1, inner conductor

Copper is the main material of the inner conductor and can be in the form of annealed copper wire, annealed copper tube, and copper clad aluminum wire. Typically, the small cable inner conductor is a copper wire or copper clad aluminum wire, while the large cable uses a copper tube to reduce cable weight and cost. The outer conductor of the large cable is embossed so that sufficient bending properties can be obtained.

The inner conductor has a great influence on the signal transmission because the attenuation is mainly caused by the resistance loss of the inner conductor. The conductivity, especially the surface conductivity, should be as high as possible. The general requirement is 58MS/m (+20°C), because at high frequencies, the current is only transmitted in a thin layer on the surface of the conductor. This phenomenon is called Skin effect, the effective thickness of the current layer is called the skin depth. Table 1 shows the skin depth values at specific frequencies for copper tubes and copper clad aluminum wires as inner conductors.

The quality of the copper material used for the inner conductor is very high. It is required that the copper material should be free of impurities and the surface is clean, smooth and smooth. The inner conductor diameter should be stable with a small tolerance. Any change in diameter will reduce impedance uniformity and return loss, so the manufacturing process should be precisely controlled.

2, the outer conductor

The outer conductor has two basic functions: the first is the function of the return conductor and the second is the shielding effect. The outer conductor of the leaky cable also determines its leakage performance. The outer conductors of the coaxial feeder cable and the super-flex cable are welded by embossed copper tubes. The outer conductors of these cables are completely enclosed and do not allow any radiation from the cable.

The outer conductor is usually formed by longitudinally covering a copper strip. On the outer conductor layer, there are slits or small holes in the longitudinal or transverse direction.

Slotting of outer conductors is more common in embossed cables. The groove is formed by equidistant cutting of the ridge peaks in the axial direction. The proportion of the cut portion is small, and the slot pitch is much smaller than the transmitted electromagnetic wavelength.

Obviously, the non-leakage type cable can be processed into a leaky cable by cutting the outer conductor peak of a common crepe type cable commonly found in a non-leakage type cable at an angle of 120 degrees to obtain a suitable slot structure. The shape, width and slot structure of the leaky cable determine its performance.

The copper material for the outer conductor should also be of good quality, high electrical conductivity and no impurities. The outer conductor size should be tightly controlled within tolerances to ensure uniform characteristic impedance and high return loss.

3. Insulating medium

RF coaxial cable media is much more than just insulation. The final transmission performance is determined mainly after insulation. Therefore, the choice of dielectric material and its structure are very important. All important properties, such as attenuation, impedance, and return loss, are strongly related to insulation. The most important requirements for insulation are:

The relative dielectric constant is low, and the dielectric loss angle factor is small to ensure small attenuation;

The structure is consistent to ensure uniform impedance and large return loss;

Mechanical properties are stable to ensure long life;

Waterproof and moisture proof.

Physical high foam insulation can meet all of the above requirements. With advanced extrusion and gas injection processes and special materials, the degree of foaming can reach more than 80%. Such electrical performance is close to that of air-insulated cables. In the gas injection method, nitrogen is directly injected into the dielectric material in the extruder, and the process is also referred to as a physical foaming method. In contrast to the chemical foaming method, the degree of foaming can only reach about 50%, and the dielectric loss is large. The foaming structure obtained by the gas injection method is uniform, which means that the impedance is uniform and the return loss is large.

Our RF cables have excellent electrical properties due to their low dielectric loss angle and high foaming. The characteristics of the foaming medium are more important at high frequencies, and it is this special foaming structure that determines the very low attenuation performance of the cable at high frequencies.

The unique multi-layer insulation (inner layer-foam layer-outer layer) co-extrusion process can obtain a uniform and closed foam structure, with stable mechanical properties, high strength and good moisture resistance. In order to maintain good electrical performance of the cable in a humid environment, we have deliberately designed a cable: a thin solid core PE on the outer surface of the foamed insulation layer. This outer layer is effective in preventing moisture intrusion and protects the electrical properties of the cable from the outset. This design is especially important for leaky cables with open outer conductors. In addition, the insulating layer is tightly wrapped around the inner conductor by the inner thin layer, further improving the mechanical stability of the cable. Moreover, the thin layer contains special stabilizers, which guarantee compatibility with copper and guarantee the long-term service life of our cables. With the right inner layer of material, you can get satisfactory performance, such as moisture, adhesion and stability.

This multi-layer insulation design (inner layer - foam layer - outer layer) can achieve excellent electrical performance and stable mechanical properties at the same time, thus improving the long-term service life and reliability of our RF cable.

4, sheath

The most common sheath material for outdoor cables is black linear low density polyethylene, which has a density similar to that of LDPE but is comparable in strength to HDPE. Conversely, in some cases, we prefer HDPE, which provides better mechanical properties and resistance to friction, chemical, moisture, and environmental conditions.

UV-resistant black HDPE withstands climatic stresses such as extremely high temperatures and extreme UV rays. When emphasizing the fire safety of cables, low-smoke, halogen-free flame retardant materials should be used. In the leaky cable, in order to reduce the spread of fire, a fire-retardant strip can be used between the outer conductor and the sheath to keep the easily melted insulating layer in the cable.

Contact: Mr. Wong(Tech)

Phone: +86-15021372007

Tel: 021-66030982

Email: shhuiyong@163.com

Add: Building A, 260 Yuantai Rd, Baoshan District, Shanghai