Mechanical stability of low-loss steady-phase cable

The mechanical stability of the same axis cable has been proposed in recent years, and there are few reports on its mechanism research in the national watch. When the cable is subjected to mechanical force, extrusion, stretching, tortuosity and torsion may occur, and the phase change principle analysis is also very complicated. Below, we analyze its effect on phase stability only from the most common tortuosity changes.

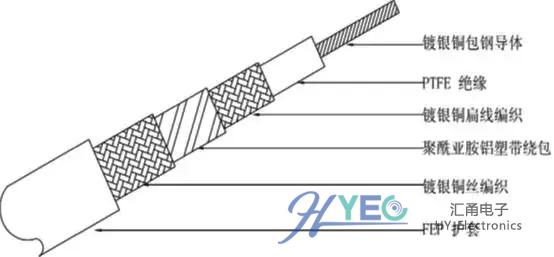

Figure: Coaxial cable phase and phase change see formula

It can be seen from the formula that the cable phase change mainly depends on the mechanical length change rate and the equivalent dielectric constant change rate. When the cable is bent by mechanical force, the phase change is mainly caused by the mechanical length change.

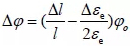

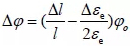

When the coaxial cable is bent, the outer side of the cable is stretched due to the unequal radius of the zigzag of the components, and the inner side of the cable is squeezed, which then causes the mechanical length to change. The maximum possible extension length of the outer conductor of the coaxial cable (ie the maximum elongation length of the cable) Δl can be expressed by the formula.

Where r is the tortuous radius of the cable, mm; D is the insulator diameter, mm; I is the cable meander length (1 = 2rθ, θ is the meander angle).

It can be concluded that the length change Δl caused by the tortuosity is related to the thickness of the cable itself (insulation diameter D), the tortuous radius r, and the tortuous length l. The thicker the cable, the smaller the tortuous radius, and the larger the meander angle, the greater the change in cable zigzag length and the greater the phase change. The above analysis is carried out under ideal conditions in which the conductor and the insulation in the watch are not relatively displaced when the cable mechanism is very tight and tortuous. When the actual cable is twisted, there will be a relative displacement between the conductor and the insulation in the watch, and then the cable phase will change.

Therefore, when designing the steady-phase cable, attention must be paid to the tightness and stability of the structure, and the relative sliding between the conductor and the insulation in the surface should be avoided as much as possible.

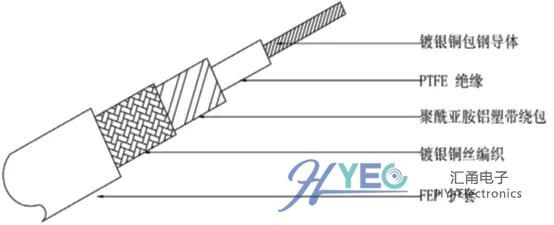

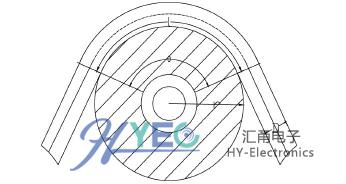

Figure: PTFE insulation, silver-plated copper tape wrap, silver-plated copper wire weaving structure

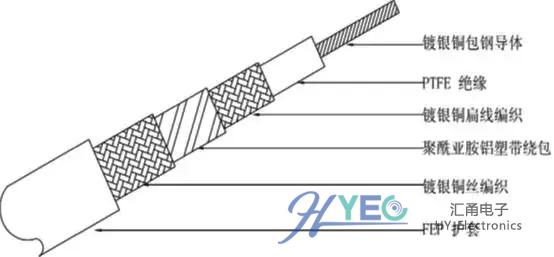

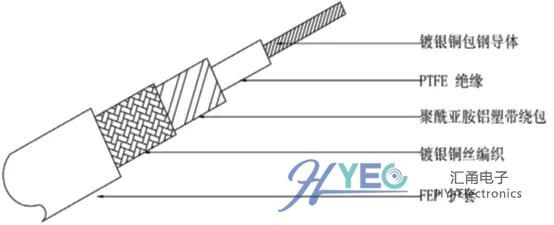

Figure: PTFE insulation, silver-plated copper flat wire weaving, composite aluminum mold winding, silver-plated copper wire weaving structure